Innovative Mechanical Parts Laser Cutting Techniques to Boost Your Productivity

Revolutionize Your Machining with a CNC Controller: A Complete Guide

April 15, 2023

The Importance of Quality in Industrial Rubber Products

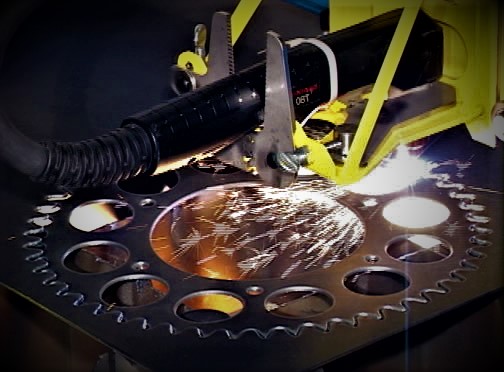

April 19, 2023When it comes to manufacturing mechanical parts, precision and accuracy are crucial for ensuring the functionality and longevity of the final product. One of the key methods for achieving this level of precision is laser cutting. Laser cutting is a highly efficient and accurate technique that is widely used in the manufacturing industry. In this article, we will discuss innovative mechanical parts laser cutting techniques that can boost your productivity.

High-Speed Laser Cutting

High-speed laser cutting is a technique that uses a high-powered laser beam to cut through materials quickly and accurately. This technique is ideal for manufacturers who need to produce a large number of parts quickly without sacrificing quality or accuracy. High-speed mechanical parts laser cutting is particularly useful for cutting thin materials, such as sheet metal, and can be used to cut complex shapes with ease.

3D Laser Cutting

3D laser cutting is a technique that uses a high-powered laser beam to cut through materials in three dimensions. This technique is ideal for manufacturers who need to create complex parts with intricate designs. 3D laser cutting is particularly useful for creating prototypes, as it allows manufacturers to create parts quickly and accurately without the need for expensive tooling.

Fiber Laser Cutting

Fiber laser cutting is a technique that uses a fiber optic laser to cut through materials. This technique is ideal for manufacturers who need to cut through thick materials, such as steel, quickly and accurately. Fiber laser cutting is particularly useful for creating parts with high levels of precision, as it allows manufacturers to cut through materials with greater accuracy than traditional laser cutting techniques.

Laser Marking

Laser marking is a technique that uses a high-powered laser beam to mark materials with text, images, or barcodes. This technique is ideal for manufacturers who need to create parts with permanent markings, such as serial numbers or part numbers. The Laser marking is particularly useful for creating parts with high levels of traceability, as it allows manufacturers to track parts throughout the manufacturing process.

Laser Engraving

Laser engraving is a technique that uses a high-powered laser beam to engrave materials with text or images. This technique is ideal for manufacturers who need to create parts with permanent branding or logos. Laser engraving is particularly useful for creating parts with high levels of aesthetic appeal, as it allows manufacturers to create intricate designs with ease.

Conclusion

In conclusion, laser cutting is a highly efficient and accurate technique that widely uses in the manufacturing industry. By incorporating innovative mechanical parts laser cutting techniques such as high-speed laser cutting, 3D laser cutting, and fiber laser cutting, laser marking, and laser engraving, manufacturers can boost their productivity and create high-quality parts with greater accuracy and efficiency. If you are looking to improve your manufacturing processes, consider incorporating these innovative laser cutting techniques into your production line.

NEWSLETTER